Olympic

Park North Park

|

|

Whole Project Award

Project Team

Client: Olympic

Delivery Authority

Designer: Atkins

Construction: Skanska

Artist: Martin

Richman

Lighting: Atkins

Bridge architect: Allies

and Morrison

The Project

The Olympic Park is a 2.5 square-km site featuring a number

of waterways and links to surrounding areas via highway, cycleway and

rail networks. The bridges and highways provide the backbone to the

park’s infrastructure. The Olympic Park is shown in Figure 1 and for

the purpose of construction logistics the site was split into the North

and South Park. The North and South Park consist of 20 km of roads,

13 footbridges, 11 km of retaining walls, 7 highways bridges and 6 underpasses.

The Games venues that were located in the North Park included the Basketball

Arena, the Copper Box (handball), Velodrome, the Olympic Village and

the Press and Broadcast Centre. The North Park infrastructure included

retaining walls, highways, secondary roads, one land bridge, one highway

bridge, six existing bridges and two underpasses.

Figure 1: Master plan for the Olympic

Park (copyright: Olympic Development Authority (ODA))

The highways, land and foot bridges form part of a family of bridges across the Olympic Park and were designed to blend and compliment the surrounding landscape. The highways, retaining walls and bridge designs reflected the Olympic Delivery Authority’s (ODA) vision of creating high quality design with a coherent approach to sustainability, inclusivity and security.

Upon award (26.07.2012), the North Park SBH (Lot 1) project is the joint highest scoring CEEQUAL project to date, together with the Olympic Park Wetland Bridges. Both projects achieved a CEEQUAL ‘Excellent’ Whole Project Award (98.3%).

| Project / objective |

Recycled content by value |

Recycled aggregate by weight |

Sustainable Transport |

Reuse of on-site demolition

material site-wide |

CEEQUAL Energy and Carbon Score |

CEEQUAL Whole Project Award |

| ODA target |

20% |

25% |

50% |

90% |

N/A |

>60% |

ODA Lot 1 |

47% |

59% |

72% |

98% |

100% |

98.3% |

Table 1. Summary of Olympic Park Structure, Bridges and Highways Lot 1 performance against the ODA's targets.

Project Management

In the support of the ODA’s aspiration to create the most

sustainable Olympic and Paralympics Games ever, several guidance documents

were provided to the design and construction team to ensure priority

themes were embedded in the design and construction of the project.

Environmental assurance procedures were in place to track performance

against a range of Key Performance Indicators (KPI), including the requirement

to achieve at least a CEEQUAL Whole Project rating of ‘Very Good’

– further details on the KPIs can be found in the ODA Sustainable

Development Strategy

http://www.london2012.com/publications/sustainable-development-strategy-full-version.php.

Materials and Waste

Through the reuse of site reclaimed materials in the abutments and

wing walls, the Olympic Park North Park SBH design supported the park

wide score of 98% of demolition materials being recycled or reused.

Material use was reduced by: reusing existing structures from Ruckholt

Road, Lea Interchange roads and Temple Mills Lane by specifying a thinner

thickness of the temporary roads in comparison to permanent roads; by

using waste plastic as kerbs for the temporary roads; and by specifying

concrete kerbs for the permanent roads with a recycled content of 47%.

Where feasible and taking into account scope and security, the design

of the highways layout was aligned with requirements for Legacy. The

topography of the site was developed and changed to reduce the number

of engineered slopes (such as making steeper slopes shallower which

then would reduce the amount of materials used).

The bridge design across the Park underwent a process of optimising

the reuse of existing bridges where possible; building new bridges for

Legacy purpose only and providing temporary bridges for the additional

Games crowd movement that can be removed in Legacy Transformation.

For example, the Northern Access Bridge (L01) between Eton Manor and

Hackney East Marsh is considered a unique structure due to its location

and functionality, as well as the desire of the local Borough for this

structure to be created as a landmark. The bridge was designed to meet

the Legacy requirements with a 5.5 metre width, while the temporary

sections of 8.5 metre width were designed to cater for the crowd flows

during the Games and will be removed during Legacy Transformation.

Figure 2: Illustration of the Northern

Access Bridge (L01) showing the permanent section in orange and

the temporary section adjacent to it. (Copyright: Olympic Development

Authority)

Prefabrication was used in the deck edge beams, cantilever, bespoke parapets and permanent participating formwork, instead of in-situ concrete. Concrete that had reduced embodied energy was achieved by specifying the use of secondary aggregates, like china clay stent and glass sand and substituting cement for Pulverised Fuel Ash (PFA).

Considerable effort was made to review the use of conventional materials and treatments and find more environmentally friendly and healthier alternatives that complied with industry standards. For example, where feasible, the majority of coatings and treatments used were volatile organic compound (VOC) free. The end of life deconstruction was considered through the incorporation of design features that made these possible, e.g. using bolted connections over welding. The ODA Materials guidance document stipulated the requirement for responsible sourcing of key building materials like aggregates, concrete and wood. The type of materials and fixings were also carefully considered during the design process, to either eliminate or minimise the need and impact of maintenance. An example of this was choosing an integral bridge design that removed the need for bridge bearing and expansion joints and therefore long-term maintenance.

Simpler construction methods, like sheet piling, were utilised wherever possible to reduce environmental impacts. Client driven waste measures included:

- The ODA Construction Waste Management Plan provided a high level framework for achieving effective waste management on site and each project was required to comply with legislation by having a Site Waste Management Plan. The client appointed a waste management contractor for the Olympic Park to manage all waste and monitor the volume of waste reused/recycled/recovered on each project.

- The Master Topography Plan for the Olympic Park was developed to ensure a balanced cut and fill. Most of the contaminated soil was treated on site at the soil hospital and the remediated soil was available to contractors to reuse on site. Across the Olympic Park >80% of soil was reused.

Energy and Carbon

The North Park SBH scored 100% in the Energy and Carbon section. The actions taken by the project included exceeding the client’s targets of 20% recycled content (by value), 25% recycled aggregates (by weight) and 50% (by weight) sustainable transportation of materials.

The designer and contractor supported the obtainment of these targets through:

- The use of site reclaimed materials for gabion baskets (see Figure 3);

- Substituting cement for PFA;

- Replacing primary aggregates with secondary aggregates (e.g. glass sand and china clay stent);

- Including recycled materials in flexible and rigid pavements;

- Using waste plastic for temporary kerbs;

- Reusing existing structures, designing for Legacy where feasible, choosing drainage pipes which use recycled aggregates as bedding material (e.g. concrete or clay) and reducing the pavement thickness to be thinner for a 4 year design life to 40 year design life.

Overall, the project achieved 47% recycled content (by value) against a target of 20%, 59% recycled aggregates (by weight) against a target of 25% and 72% of materials were delivered by sustainable transport against a target of 50%.

|

|

|

Figure 3: Reclaimed material in gabion baskets (Copyright:

Skanska), recycled waste plastic kerbs (Copyright: Skanska),

cold lay asphalt (Copyright:Skanska) & rail deliveries

(Copyright: Olympic Development Authority).

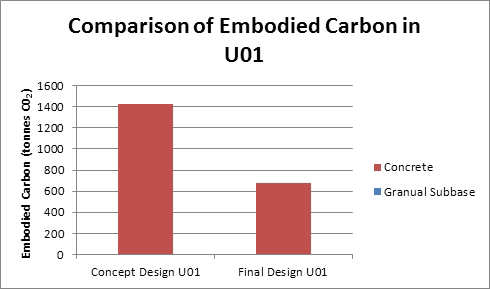

An embodied energy statement demonstrated the actions

that had been taken to reduce the energy and carbon consumption associated

with the key building materials — aggregates, concrete and steel

for the infrastructure design at key stages during the whole life

-cycle.

Case studies carried out during the design determined a:

Figure 4: Comparison of embodied energy from concept

to final design of U01

The size reduction of the underpass U01 meant that the materials used for concrete, reinforced steel and pavement had been reduced as follows:

-

2870m3 concrete at scheme compared to 1355m3 concrete used in construction

-

8.7kg reinforcement steel at scheme compared to 4.1kg used in construction

-

408m3 granular sub base at scheme compared to 204m3 used in construction

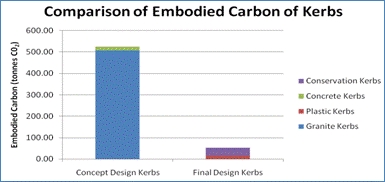

2. A 90% carbon reduction of the kerb selection from concept to final design

Figure 5: The embodied carbon is compared in kerbs

selection from concept to final design. (Copyright: Atkins)

The ODA Lighting Strategy set out how to minimise energy consumption associated with lighting the Olympic Park. There is a combined, cooling, heat and power (CCHP) plant on the site which provides power to the site with a biomass boiler and a gas-fired boiler. The only electrical power requirement for SBH is for the street and bridge lighting. The highways lighting design specified energy efficient lamps with associated electronic control gear (future proofed for remote control dimming and a lantern that minimizes light spill). Electronic control gear is approximately 15% more energy efficient than conventional control gear. Feature lighting on the box girder uses LED luminaries with lighting controls which switch on at dusk and switch off at midnight or as specified by the client. Lighting was designed out of the tow path and the box girders of the bridges are trapezoidal to optimise the amount of daylight underneath the bridge.

Energy consumption and carbon emissions in construction

The ODA developed a Code of Construction Practice which included measures to save energy on site. During construction carbon reductions were achieved through various initiatives, none more challenging or successful than switching all ‘road-worthy vehicles’ to run on biodiesel derived from sustainably sourced waste UK rapeseed oil. This involved the full spectrum of site vehicles from the staff minibuses, foreman’s pickup trucks/4x4s, to operatives site vans and ‘flatbed’ Transits.

![]()

|

|

|

|

Figure 6. From left: UK rapeseed

– retailed cooking oil – reclaimed used cooking oil processed

through transesterfication

(removal of fatty acids) – biodiesel fuelled site vehicle.

The drivers for this trial were:

-

To align with our client’s focus of reducing the carbon intense activities during the construction phase.

-

Qualify for additional CEEQUAL points in the notoriously challenging Energy and Carbon section.

-

Reduce costs associated with carbon legislation (CRC energy efficiency scheme).

The key challenges overcome were:

-

Ensuring the fuel was responsibly sourced and compliant with Skanska’s ‘Policy on Bio fuels’. This involved duty of care checks with its supply chain to check the fuel was a waste UK product and not derived from Palm Oil.

-

Sourcing quality fuel certified to the international standard for biodiesel EN 14214.

-

Accepting the financial risk of vehicle warranties being void (a consequence of using greater than 7% concentration of biodiesel).

-

Challenging the ODA framework fuel supplier to provide us with biodiesel from another supplier, overcoming contractual barriers.

|

|

|

Figure 7. Site set up of biodiesel tank, mileage/consumption log and compulsory spill prevention measures.

Lessons learned

Biodiesel is a cost effective solution to reducing carbon emissions when: the fuel is from a sustainable source; the quality is to European standard; and the project team accept the financial implications of the vehicle warranties being void. As a result, direct carbon dioxide (CO2) emissions were reduced by 50% and cost savings of 12% were achieved.

|

C02 |

Cost (£) |

Mineral Diesel |

2.67kg CO2e |

£1.15/l |

B50 Biodiesel |

1.34kg CO2e |

£1.01/l |

| Saving (Carbon / Cost) |

50% |

12% |

Biodiversity and Ecology

The Olympic Park Biodiversity Action plan included measures to enhance habitats on the Olympic Park through the provision of habitats for birds and bats. Highway Bridge H01 incorporated a total of 10 bespoke bat boxes underneath the bridge deck. Traditionally, bridges are seldom used for habitat creation so this was a new approach (please see Figure 4). The retaining walls provided habitats for reptiles.

Figure 8: Bespoke bat boxes are fitted underneath

bridge H01. (Copyright: Atkins)

Transport

The ODA requested that 50% (by weight) of materials be transported

to site by sustainable transport (rail or water). North Park SBH Lot

1 achieved 72% (by weight) sustainable transport of materials. The

project design team specified bulk materials, such as secondary aggregates

for the concrete to be transported to the site by rail, wherever possible.

Water Resources and the Water Environment

The surface water drainage system discharges into the River

Lea and was designed as a sealed pipe work system to protect the groundwater

aquifer from surface contamination. The drainage system incorporates

a low maintenance carrier drainage system with silt traps and gullies

for pollution control. The previous combined sewer network on the

site was removed and separate surface and foul water systems provided.

This has improved the water quality within the River Lea.

The Olympic Park was designed to minimise flood risk. This was achieved

by installing previous overland flow routes, which in times of flood,

are intercepted and diverted into the River Lee, reducing the flood

risk to approximately 4000 properties (Please see Figure 5).

Figure 9: Construction of a new culvert which intercepts

the overland flood route, thereby reducing flood risk to

approximately 4000 properties. (Copyright: Olympic Development Authority)

All riverside planting was delivered to site as pre-established plants that did not require irrigation to become established. Furthermore, the design incorporated drainage outfalls into three frog ponds and two wet woodlands, providing irrigation feed water, habitat water and runoff attenuation.

A piling risk assessment was undertaken to determine

whether during the piling of bridge foundations, continued flight

auger or bored cast-in-situ piling would minimise the risk of cross

contamination to surface or ground water. Bored cast-in-situ piling

was chosen because it had a reduced environmental impact.

Relations with Users and Aesthetics

The bridge deck and parapets were designed to the ODA Inclusive Design Standards and accommodates users of all abilities including cyclists, pedestrians and disabled people. The designs of artist Martin Richman are included in the underpass U01 (Refer to Figure 6 below) which were lined with recycled glass ‘beads’ set into a cement based plaster ground. The ‘beads’ were arranged in colour groups to create large scale spiralling bands running up the walls and across the ceiling. The glass bead colours are in the warm red colour spectrum, responding to a need to give a warm, welcoming feeling to a potentially hostile space. It is also a rational response to the context whereby the underpass essentially cuts through from one grass embankment to another. The design accentuates the perceptual experience of going from a green and cool orthogonal space to the organic swirling reds of the interior of the underpass. The spiral patterns here also suggest energy of flow and vitality, which are appropriate to the imagery of cycling and turning wheels.

Figure 10: The underpass U05 with art by Martin Richman

(Copyright: Olympic Development Authority)

As part of the Urban and Landscape Design Framework each waterway on the Olympic Park has been designated a different colour, contributing to finding a way which is recognisable from the towpaths on the soffit of the box girder. The four colours applied to the soffits of the bridges were selected from the London 2012 brand identity palette (orange, pink, blue and green) to retain a memory of the Olympic and Paralympics Games in the Legacy Parklands. The Highways Bridge H01 is assigned orange (Figure 7).

Figure 11: To aid way finding Highways bridge H01

is coloured orange

(copyright: Allies and Morrison)